I-static incling crystallizer eyenziwe nge-Dimple Pillew Plates Heat Exchanger

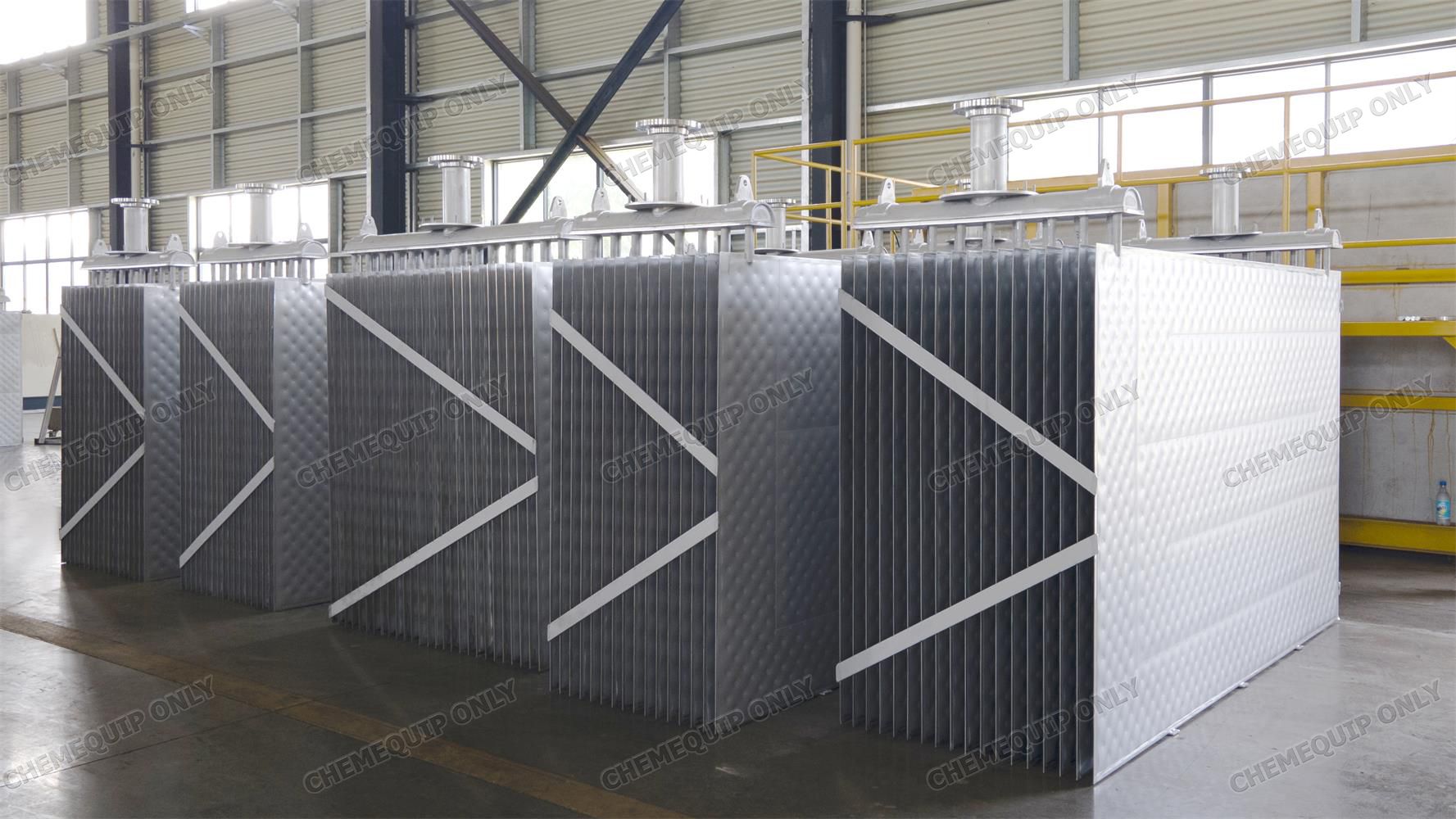

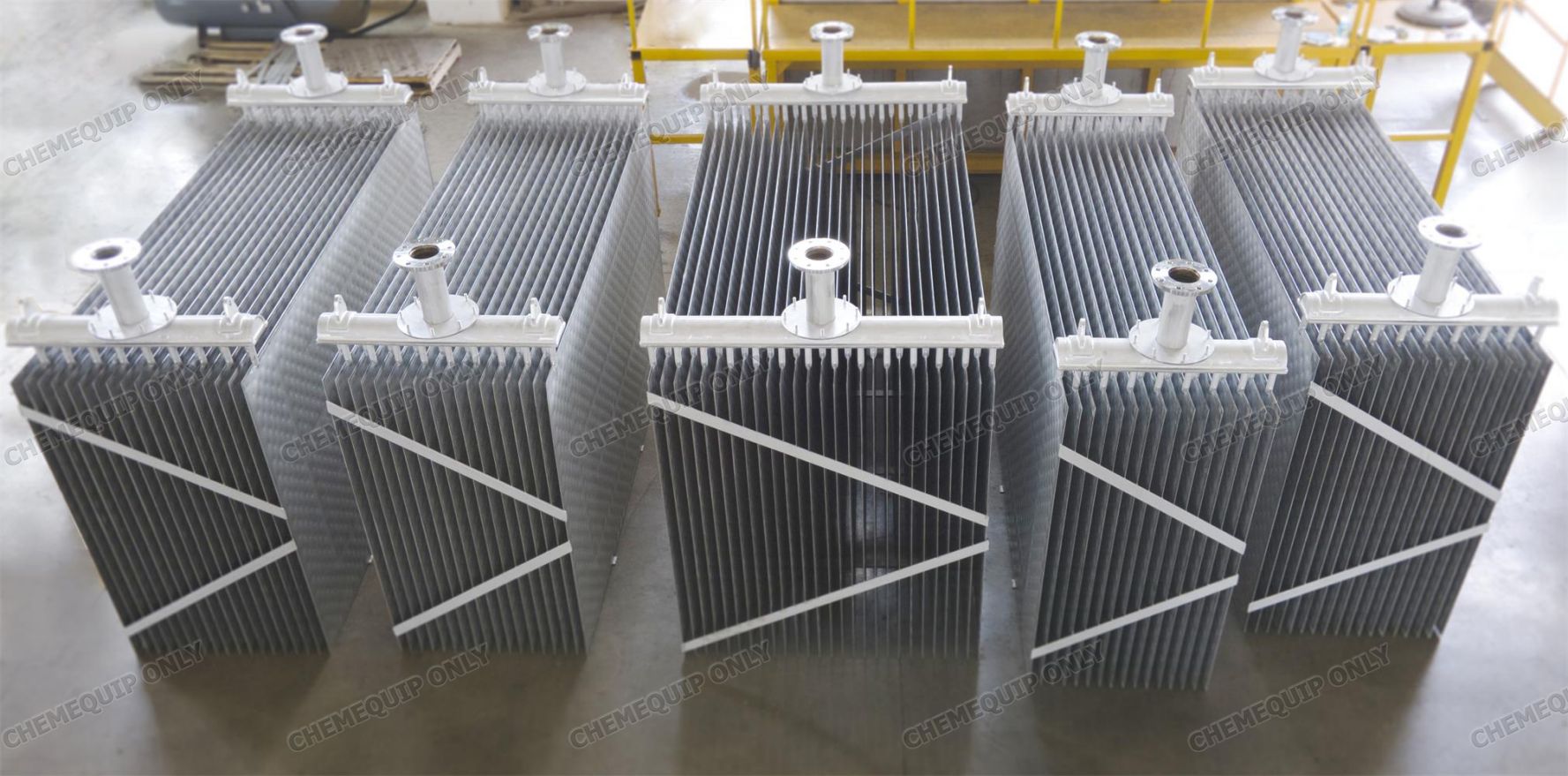

I-static incling crystallizer isebenzisa ipuleti elikhethekile lokushisa lokushisa (ipuleti le-petatecoil) ngokushisa okuphakathi noma okupholile okuphakathi nendawo, okusetshenziselwa ukufudumeza kwangaphakathi kokujikeleza noma kwenqubo yokupholisa. Amapuleti okushintshaniswa kokushisa abekwe ngokuqondile kwikhabethe le-crystallizer, ukufudumeza noma okupholile okuphakathi nendawo okushisa kancane noma kupholisa umama okhazimulayo uketshezi olungaphansi kwendawo ebiwe. Ekugcineni, kwakhiwa ungqimba lwe-Crystalliting Plate Plate, lusebenzisa inqubo "yokujuluka" ukususa ukungcola futhi kuhlanjululwe amakristalu.

I-static incling crystallizer iyindlela yokuhlanza nokuhlukanisa umkhiqizo oqondiwe kwezinye izingxenye ngokusebenzisa amaphuzu abo ancibilikayo (i-crystallization point), futhi ukuzuza ngezinyathelo ezintathu ezinkulu, ukujuluka nokuncibilikisa.

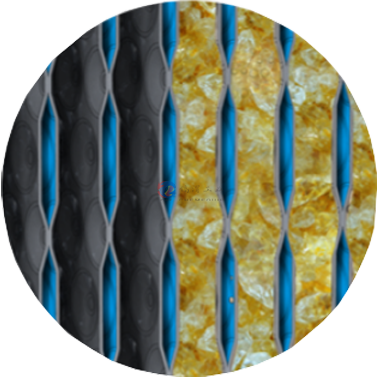

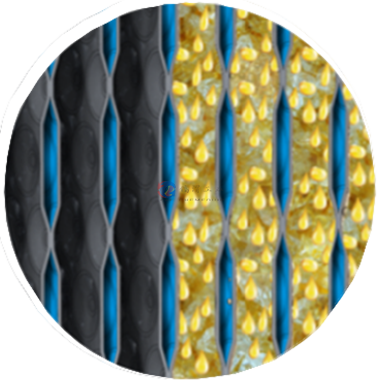

Ingxube encibilikisiwe iphoqelelwa kancane ngokudluliswa kokushisa okuphakathi nendawo ngaphansi kwephuzu le-crystallization kanye namakristalu aqonde phezulu kwamapuleti we-platecoil, akha izingqimba ze-crystallization. Ukungcola ikakhulukazi okukhona ku-Liqur kamama futhi kukhishwe ku-crystallizer.

Isendlalelo se-crystallization singahlanzwa ngokujuluka (ukuncibilika okuyingxenye), okungukuthi kancane kancane ukufudumeza endaweni yokuncibilika, khona-ke ukungcola okuhlanganisiwe nokunamathela kuzovunyelwa ngumkhiqizo oncibilikayo. Ukujuluka kuyisinyathelo esiyisihluthulelo senqubo yonke.

Ngemuva kokujuluka, izinga lokushisa lokudluliswa kokushisa okuphakathi kwenyuke ngokwengeziwe ukuze kuncibilike lonke ungqimba lwe-crystallization bese uthola umkhiqizo ovuna uketshezi.

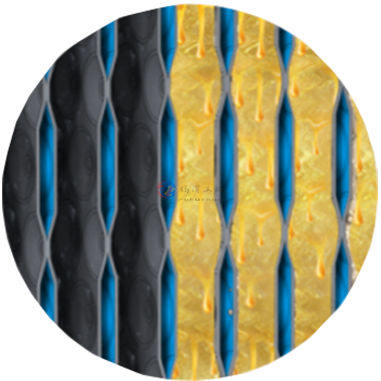

I-Platecoil Plate ingukushibilika okukhethekile kokushisa ngesakhiwo sepuleti eliphansi, esakhiwa ubuchwepheshe be-laser welding futhi inyuke, ngokugeleza kwamanzi okuyisiphithiphithi ngokweqile, okuholela ekusatshalalisweni kokushisa okushisa kakhulu kanye nokusatshalaliswa kokushisa okuphezulu. I-LT ingaklanywa futhi yenziwe ngezimo ezahlukahlukene namasayizi ngokwesidingo sekhasimende. Ipuleti le-platecoil libekwe emandleni anamandla amakhulu. Lobu buchwepheshe buhlanganisa ukwakheka kwe-anti-crystal-collapling design nge-Alokho Ubuchwepheshe Bendawo Yokukhipha Isikhala ezansi. Ingaphandle lePlatecoil Plate solvent-free crystallizer (i-static incling crystallizer) yiKhabhinethi ehlelwe nge-Inlet Inlet, ethekwini, i-port, i-Overflow Port.

| Amakhemikhali webanga le-elekthronikhi | Amakhemikhali kaPetroleum | ||

| I-phosphoric acid | Ethylene carbonate | I-paraxylene | I-benzene |

| I-Acetonitrile | I-VinyLidene Carbonate | 1,2,4,5-terramethlenzenzene | Ipheshelweshi |

| Dimethyl carbonate | Fluoroethylene Carbonate | I-DICYCLOPEENTADIENE | Iphalafini |

| Ama-polymer monomers | Amakhemikhali amahle | ||

| I-DL-LACCIDE | IBisphenol a | I-pyridine | I-TDI |

| Dichlorobelene | m-xylyliamine | I-benzoic acid | MDI |

| I-Succunonitritrile | Methacrylic acid | I-Chlororoacetic acid | I-Naphthalene |

| 1,4-butanediamine | I-acrylic acrylic acid | 1-naphthol | p-cresol |

| 1,4-DICICELANOBUTANE | Dimethyl sucan | Methylnaphthalen | I-benzoic acid |

| I-1,6-DiameInohexane | Terephthaloyl chloride | I-CyanopyriDine | I-4-ChlotoLuene |

| I-1,5-Pentanediamine | I-BIS (4-Fluorophenyl) -Ithethanone | Inhloko | I-Anhydride |

| I-benzenneliamine | I-BIS (4-Nitrofenl) ether | Diisocyanate | Chlononitrobenzennene |

| I-caplolactal | Dimethyl terephthalate | I-DICYCLOPEENTADIENE | P-tert-butylphenol |

| Ama-biochemicals | |||

| I-oleic acid | I-malic achig | Butane-1,2-diol | Erythritol |

| Itaconic acid | I-Stearic acid | I-Crotonic acid | lsosorbide |

| I-CINAMIC acid | Xylitol |

| |

1. Ukuvinjelwa kokushisa okufanayo.

2. Umjikelezo we-crystallization olawulayo.

3. Akukho ukuwa kwamakristalu ngesikhathi sokujuluka.

4. Ukususwa ngokuphelele ekuhlanzeni nasekulungiseni.

I-5. Usayizi olwenziwe ngokwezifiso nokwakheka kuyatholakala.