Khiqiza i-laser i-welder yokushisa ukushisa ipuleti njengesampula

Isinyathelo 1 Idizayini

| Ibizo | Ukucacisa | Phawula | Into uqobo lwayo | Ukushisa ukushisa okuphakathi | |

| I-Laser Welded Heater Transfer Plate yakhelwe ngokwezidingo zamakhasimende. | Ubude: Kwenziwe ngokwezifiso Ububanzi: Kwenziwe ngokwezifiso Ubukhulu: Kwenziwe ngokwezifiso | Amakhasimende angangeza uphawu lwawo. | Kutholakala ngezinto eziningi, kufaka phakathi i-304, 316l, 2205, hastelloy, titanium, nezinye | Ukupholisa okuphakathi 1. UFreon 2. I-Amonia 3. Isixazululo se-glycol | Ukushisa Okuphakathi 1. Steam 2. Amanzi 3. |

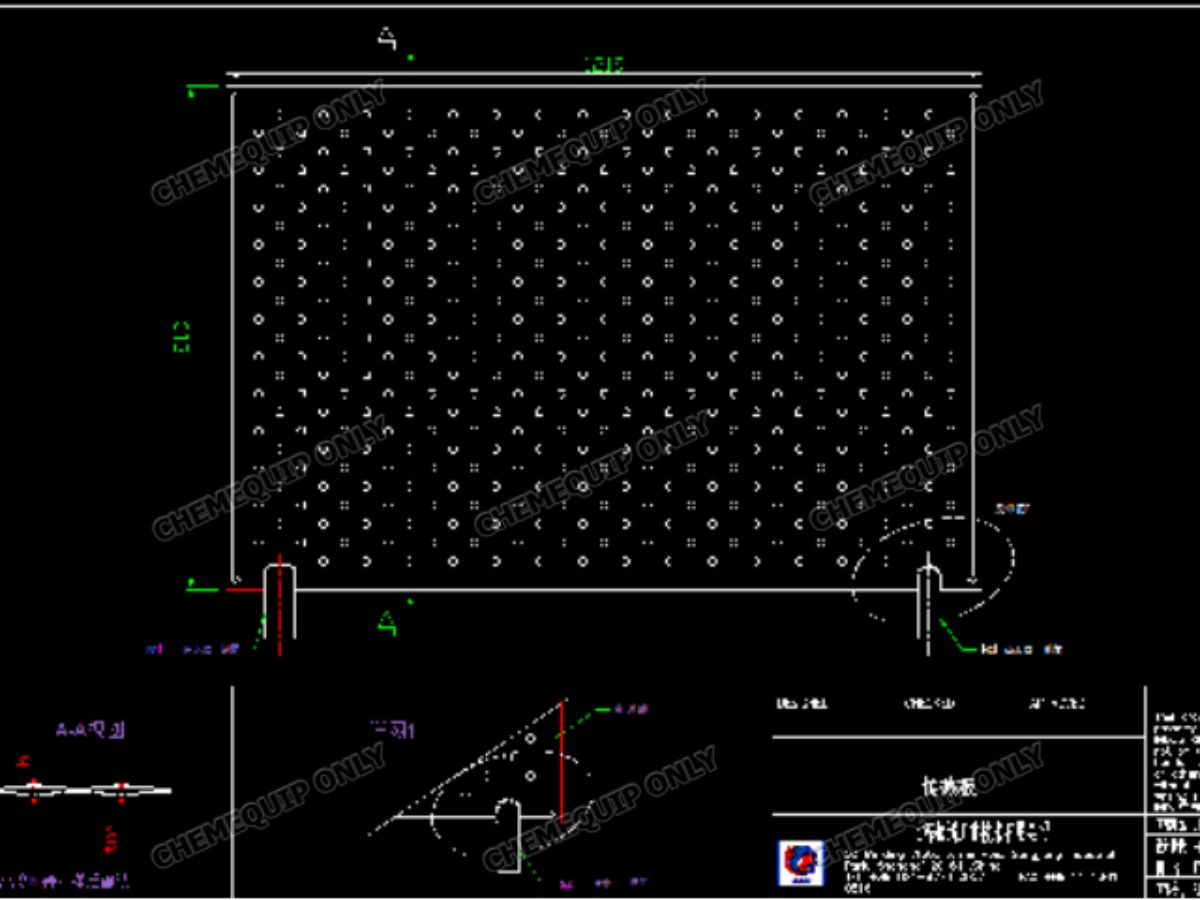

Isinyathelo 2 Umdwebo

I-ChemQuip izohlinzekaimidwebo yokuvunywaNgemuva kokuthi iphrojekthi iqinisekisiwe.

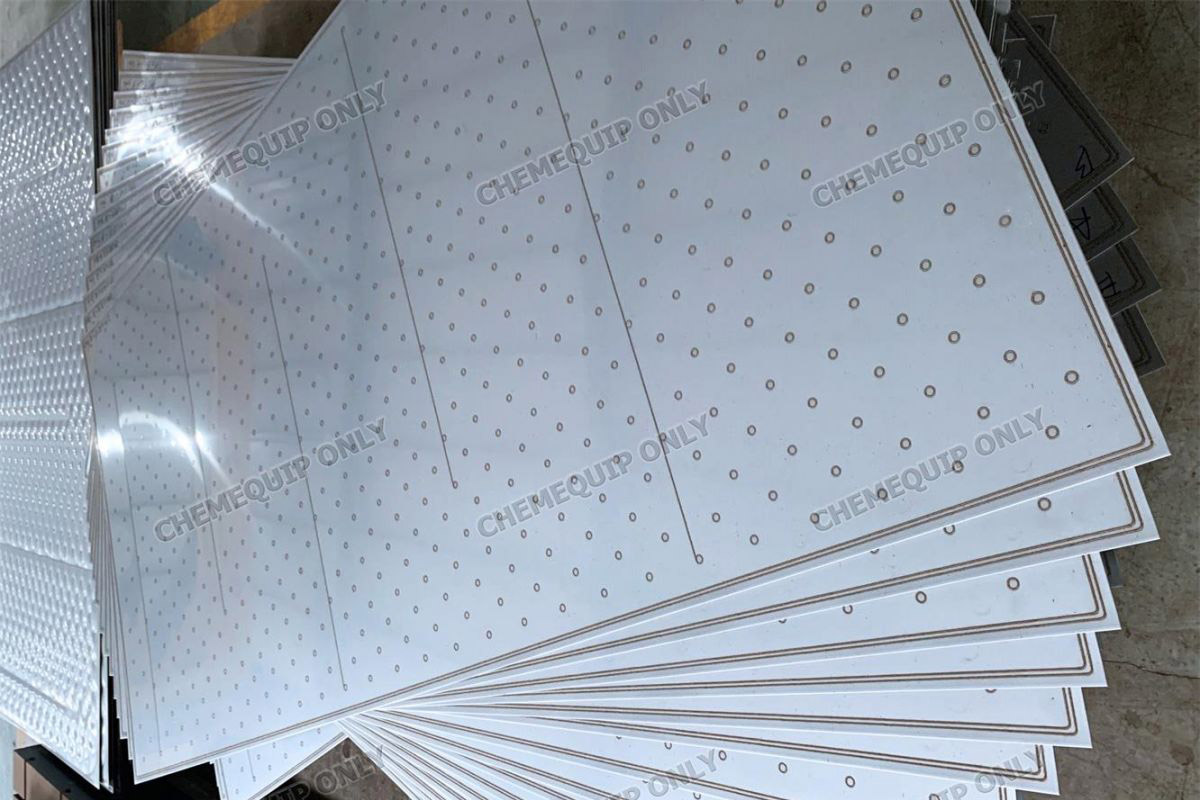

Isinyathelo 3 Lungiselela futhi usike impahla

Lungiselela impahla eluhlaza ngokuya ngezidingo.

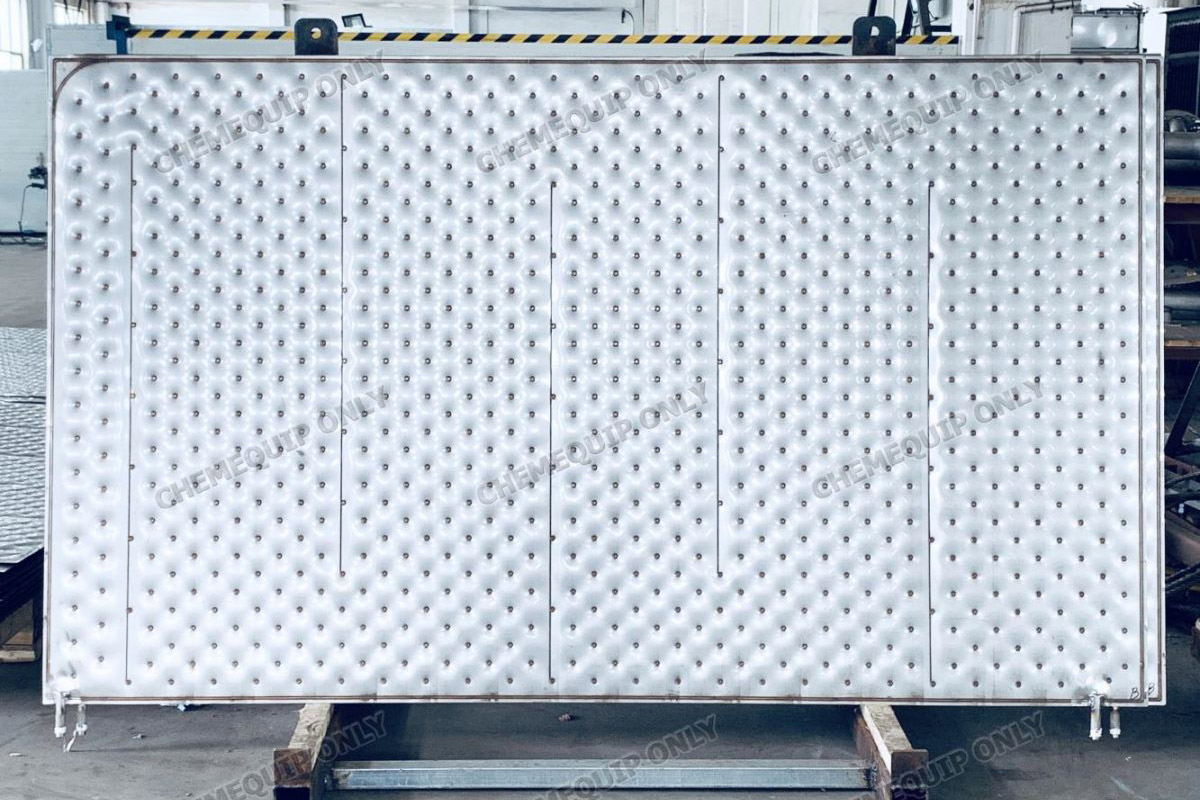

Isinyathelo 4 Laser Welding

I-Laser Welding yenziwa endaweni eyisicaba yinqubo yokufaka ishidi eliphezulu eshidi elingaphansi. Le nqubo yenziwa ngaphandle kokuguqulwa ohlangothini lomkhiqizo weshidi elingaphansi njengokuphambuka, ukupela noma ukuguquguquka.

Isinyathelo 5 - Ukwakha

Amaphaneli we-laser welded asungulwa zaba yizilinganiso ezithile ngokuya ngomklamo wakho. Isibonelo: Azikho izidingo ezingeziwe zokwakha izinto zezinwele ze-laser weldeted. Amakhanda angakhiwa njengobumba obuhlatshweziwe noma ohlanganisiwe.

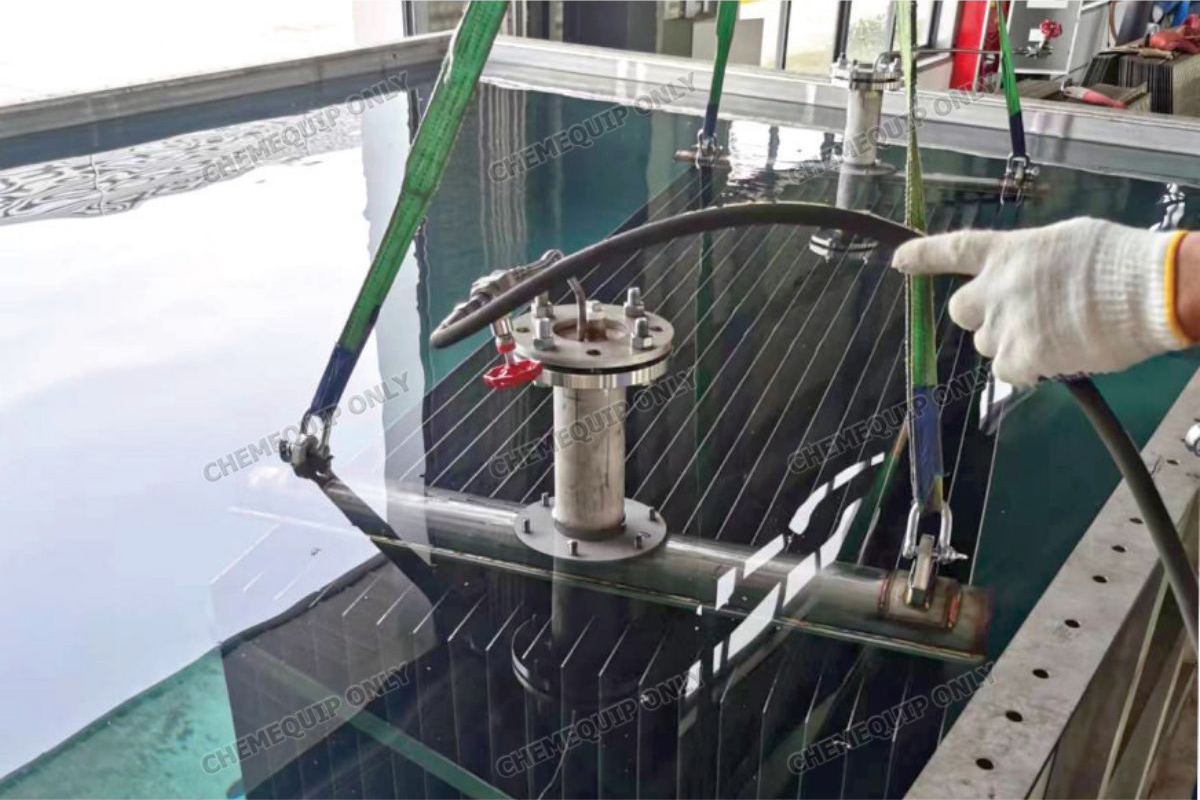

Isinyathelo 6 - Ukufakwa kwe-nozzle kanye nokwenyuka kwamanani

Faka inlet kanye nokuphuma kwamapayipi.

Isinyathelo 7 - Ukuhlola

Ukuhlolwa okuvuzayo nokunye ngaphambi kokuthumela.

Isinyathelo 8 - Iphakheji

Ukupakisha ngokuya ngamazinga okuthumela aphesheya.

Isayithi Lokukhiqiza Lokusebenza