Crystallizer e qhibilihileng e entsoeng ka dumple mosamo e plates plates Heat

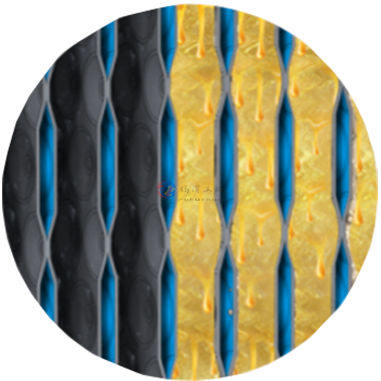

Crystallizer e qhibilihang e sebelisa poleiti e khethehileng ea mocheso (poleiti ea polasetiki) e futhumatsang kapa e pholileng, e sebelisetsoang ho futhumatsa ka hare ho potoloha. Lijana tsa phapanyetsano ea mocheso li kenngoa ka kotloloho ea kristata ea kristasta Qetellong, lenaka le hlakileng le thehoa holim'a poleiti ea mocheso ea mocheso, e sebelisa ts'ebetso ea "mofufutso" ho tlosa litšila le ho hloekisetsa likristale.

Crystallizer e qhibilihang ke tsela ea ho hloekisa le ho arola sehlahisoa se bonoang, ts'ebetso eohle e arotsoe ka har'a kristale, ho sesa le ho qhibiliha le ho qhibiliha.

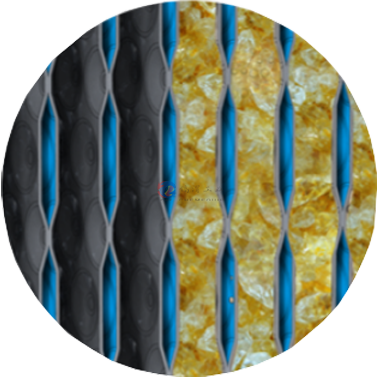

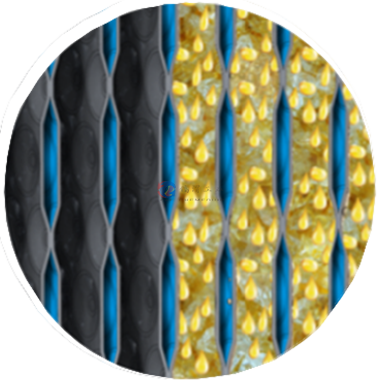

Motsoako ona o mongata o theohile butle ka tlase bohareng ntlha ea kristastranization le likristale tse tsoang holim 'a lipolanete tsa crystalliza. Litšila li teng haholo joala ba bo-mme ebile li lokollotsoe ho tsoa kristale.

Karolo ea crystallization e ka hloekisoa ka ho fufuleloa (e le 'ngoe e qhibiliha), e liehisa moea o tukang le o tloaelehileng oa ho qhibiliha. Ho fufuleloa ke mohato oa bohlokoa mohato o felletseng.

Kamora ho rohaka, mocheso oa phetisetso ea mocheso o eketsehile ka ho qhibiliha mokatong o mong le o mong oa kristastralization ebe o fumana sehlahisoa se phahameng sa metsi.

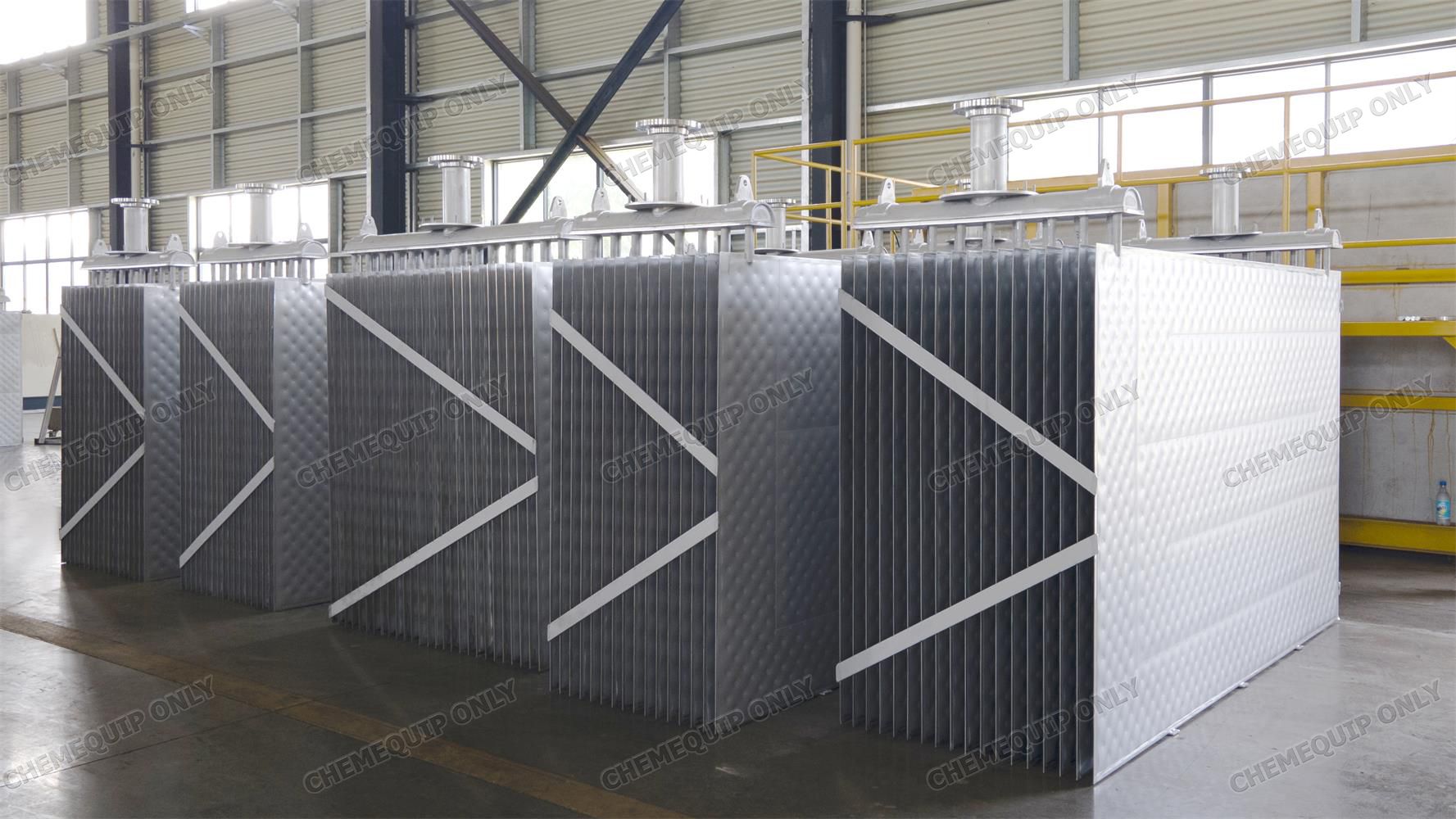

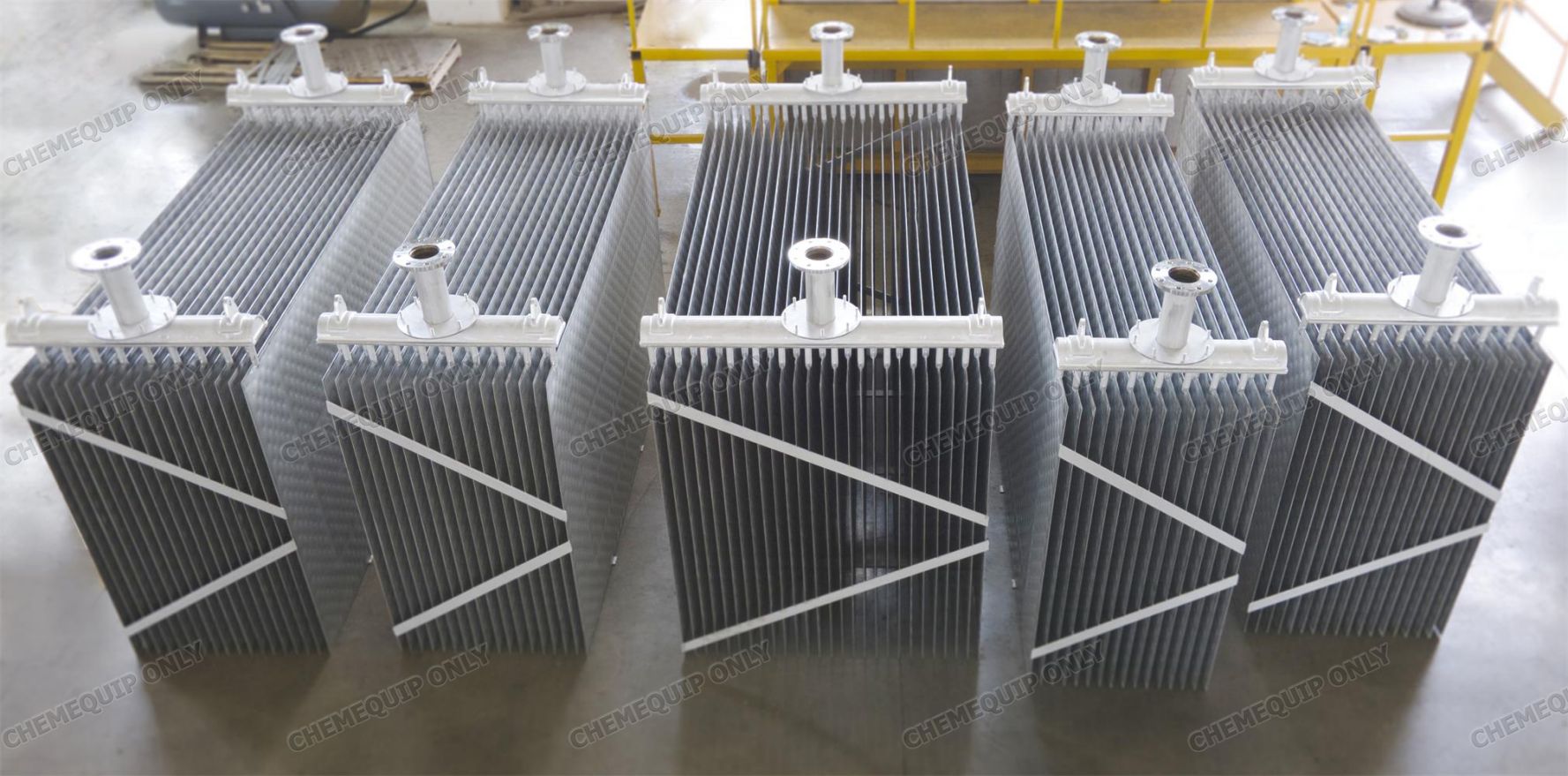

Platecoil Platecoil ke mocheso o khethehileng ka sebopeho sa poleiti e sephara, e entsoeng ke phallo e matla ea laser, e hlahisoang ka mokhoa o phahameng oa phepelo ea mocheso oa veriffor. LT e ka etsoa le ho etsoa ka libopeho tse fapaneng le tse boholo ho latela litlhoko tsa moreki. Platecoil poleiti e beoa ka ho ba le ho ja ka mokhoa o matla. Theknoloji ena e kopanya moralo oa li-crystary tse oeleng ka ho oela ha setsebi sa phapanyetsano ea sebaka se ka tlase. Bokantle ba poletecoil platellellizil platellizer (kristation crystallizer e se nang kristale

| Lik'hemik'hale tsa sehlopha sa elektroniki | Lik'hemik'hale tsa peterole | ||

| Phosphoric acid | Ethylene carbonate | Paraxylene | Benzene |

| Khoeli ea Acetonitrole | Vinylidene Carbonate | 1,2,4,4,5-tetramethylbenzene | Phenol |

| Dimethyl carbonate | Fluoroneylene carbonate | DACYCUPERNENTER | Parafinin |

| Monompors tsa Polymer | Lik'hemik'hale tse ntle | ||

| DL-lactide | Bisphenol a | Pyridine | TDI |

| Dichlorobenzene | M-xylyleanerienine | Benzoic acid | Mdi |

| Sugchisonitrile | Asiti ea methacrylic | Chlorocetic acid | Naphthalene |

| 1,4-Buaserianinine | Asiti ea acrylic acrylic | 1-Naphthol | P-CRESOL |

| 1,4-diganobubutane | Dimethyl augninate | Methylnafthan | Benzoic acid |

| 1,6-Diaminohexane | Terefthaloyl chloride | Cynokopyrine | 4-chlorotoluene |

| 1,5-pentediasines | Bis (4-fluorophenyl) -Monone | Mensol | Maleic ahydride |

| Benzenedianeriane | Bis (4-Nitrophenyl) Ether | Diordbatate | ChlonitrieroBe |

| Caprolacat | Dimberyl terefthate | DACYCUPERNENTER | P-tert-butylphenol |

| Likochemical | |||

| Oleic acid | Malic acid | Butane-1,2-Diol | Erythritol |

| Ikaccioc acid | Stearic acid | Crotonic acid | lsosoorbide |

| Cinnic acid | Xytiol |

| |

1. Tsamaiso ea mocheso ea Uniform.

2. Crystarization crystarization.

3. Ha ho na likhalase tsa likristale nakong ea ho fufuleloa.

4. Ho tlosoa ka botlalo bakeng sa ho hloekisa le ho lokisa ka botlalo.

5. Boholo ba mofuta le sebopeho se fumaneha.