E mong le e mong oa Laser Welding Pilock Plete Fosch ea Heat Exctionary bakeng sa ts'ebetso ea lijo

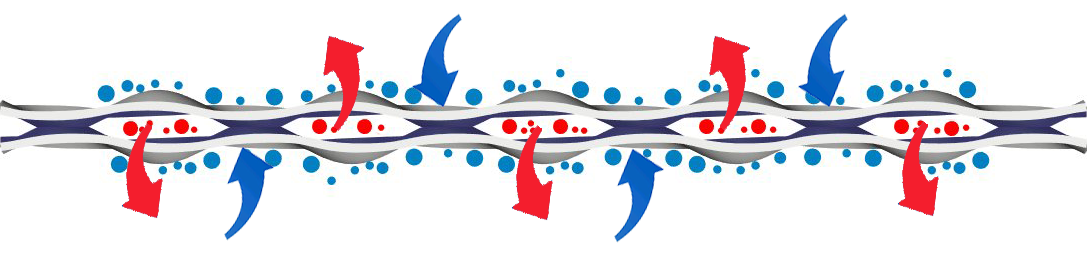

Mosamo oa mosamo oa mocheso o tsamaisoa ka mokhoa o sa feleng oa lisere tsa tšepe tse 'maloa tsa tšepe hammoho le theknoloji ea fiber Laser. Mofuta ona o ikhethileng oa mocheso oa mocheso o ka etsoa ka sebopeho le boholo bo fapaneng, 'me lits'ebelisong tse phahameng tsa mocheso. Ka tšebeliso ea laser e laoloang le ho theola liteishene, e baka litsietsi tsa metsi tse phahameng tsa metsi, e fella ka li-coefficents tse phahameng tsa mocheso.

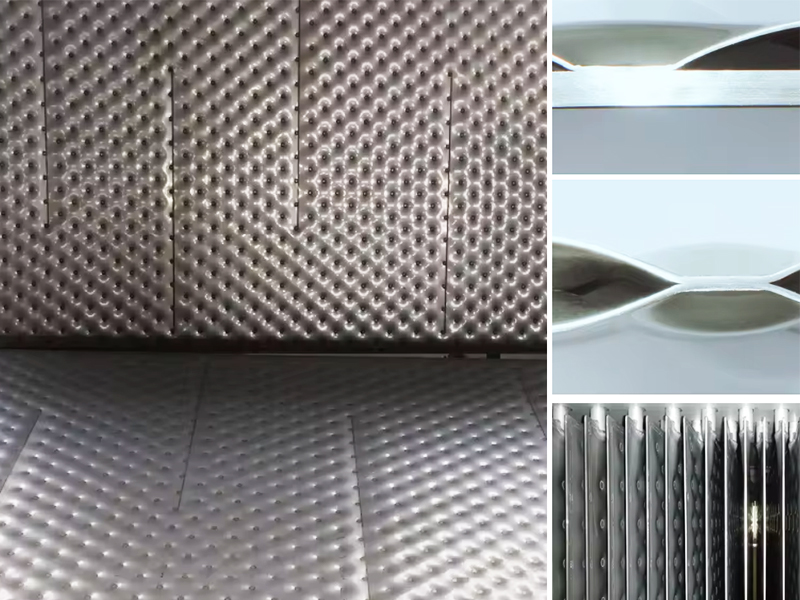

Mosamo oa mosamo oa mocheso o boetse oa bitsoa oa polasetiki Plate Foko ea mocheso, li-plates tsa methapo, Thermo plates. E entsoe ka likhetla tse peli tsa tšepe tse nang le majoe a nang le laser-le li le mongoli oa potoloka, hape o ntlafatsa ts'ebetso ea eona le ho tsebahala.

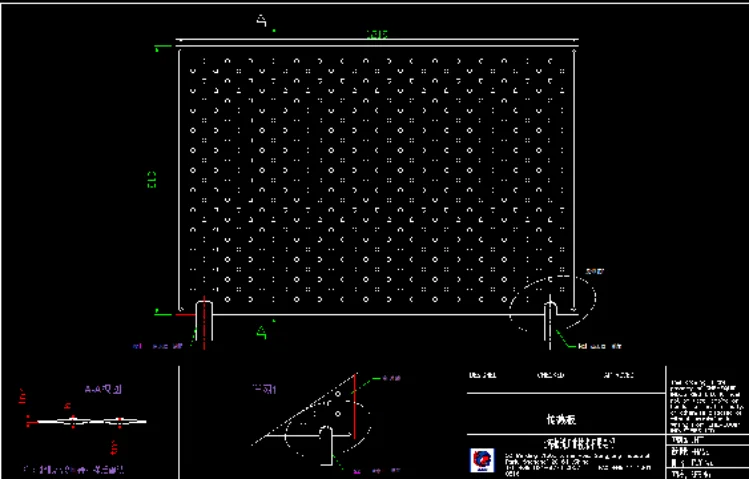

| Lebitso | TLHOKOMELISO | Brand | Lintho tse bonahalang | Phetisetso ea mocheso e mahareng | |

| Poleiti ea mosamo | Bolelele: E entsoe ka mokhoa Bophara: E entsoe ka mokhoa Bophahamo: E entsoe ka tloaelo | Bareki ba ka eketsa logo ea bona. | Fumaneha ka lisebelisoa tse ngata, ho kenyelletsa 304, 316l, 2205, Hasdloy, Tina | Ho futhumatsa mahareng 1. Freon 2. Ammonia 3. Tharollo ea Glycol | Futhumatsang medium 1. Steam 2. Metsi 3. Oli ea tsamaisang |

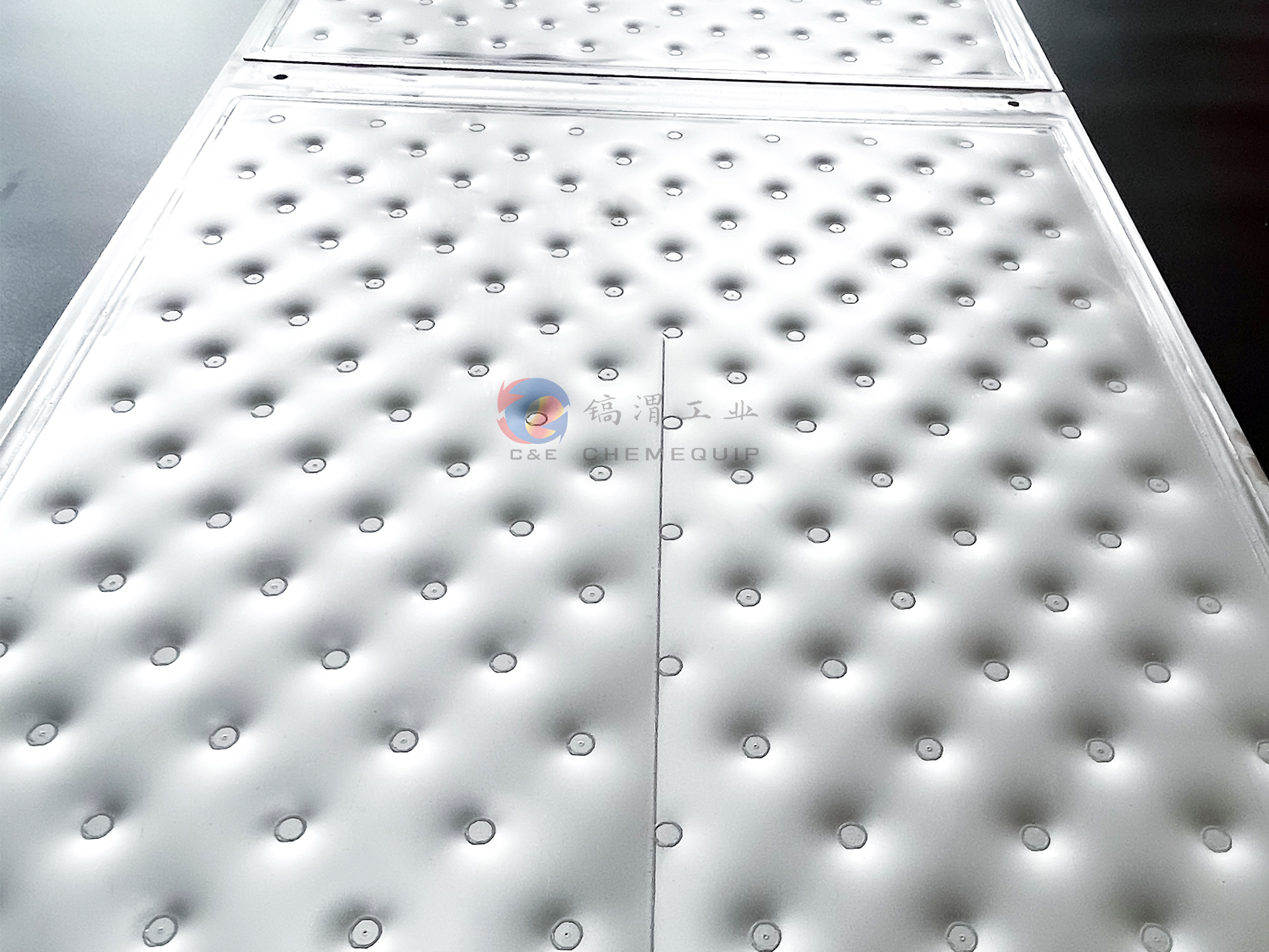

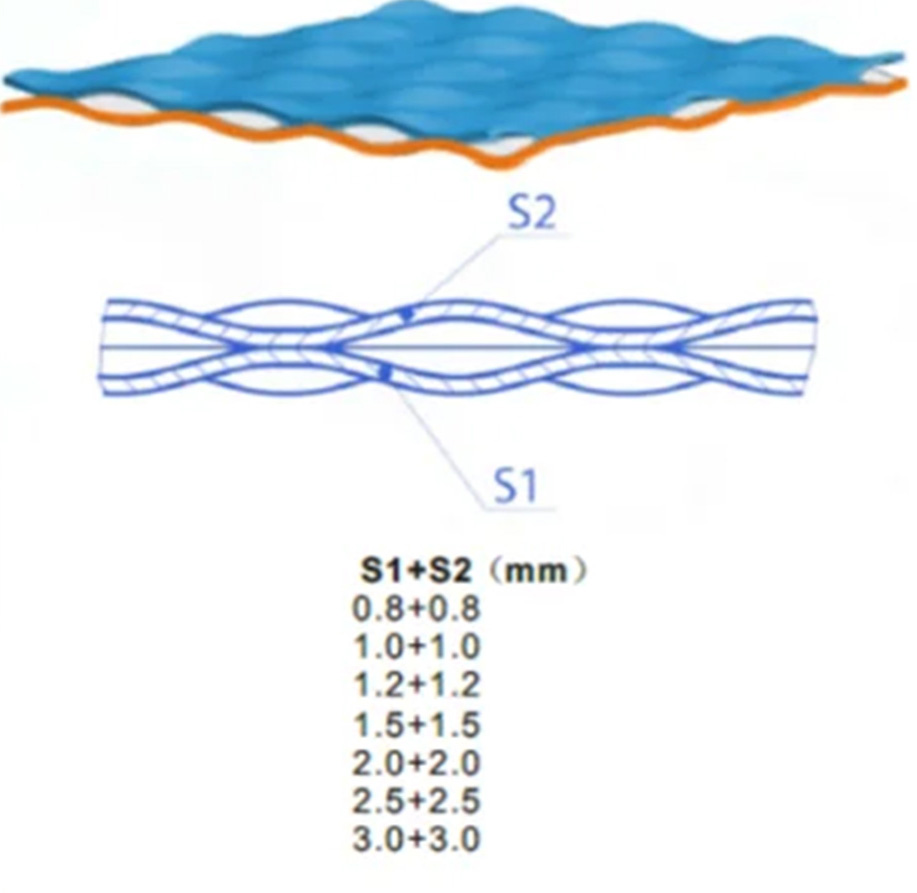

Double Endbossed Pilamo

E na le lehlakore le le leng le sephara le lehlakore le le leng le bataletseng.

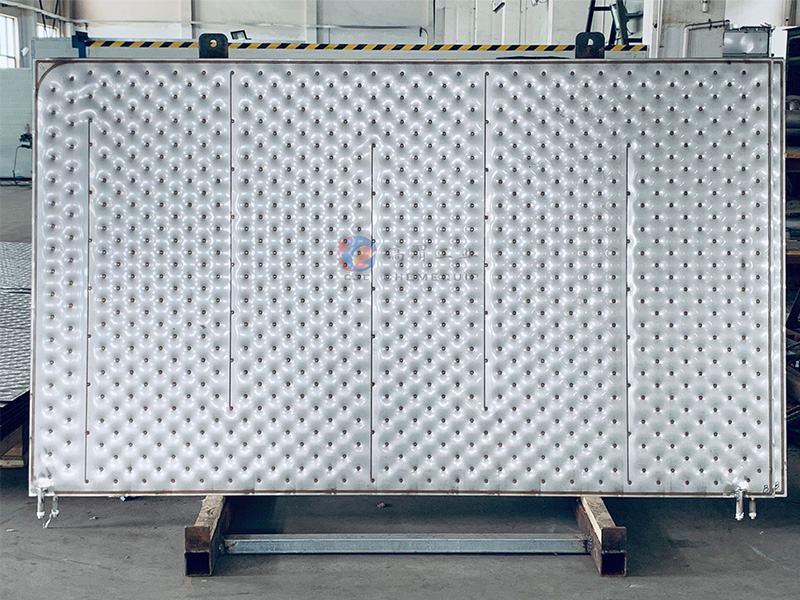

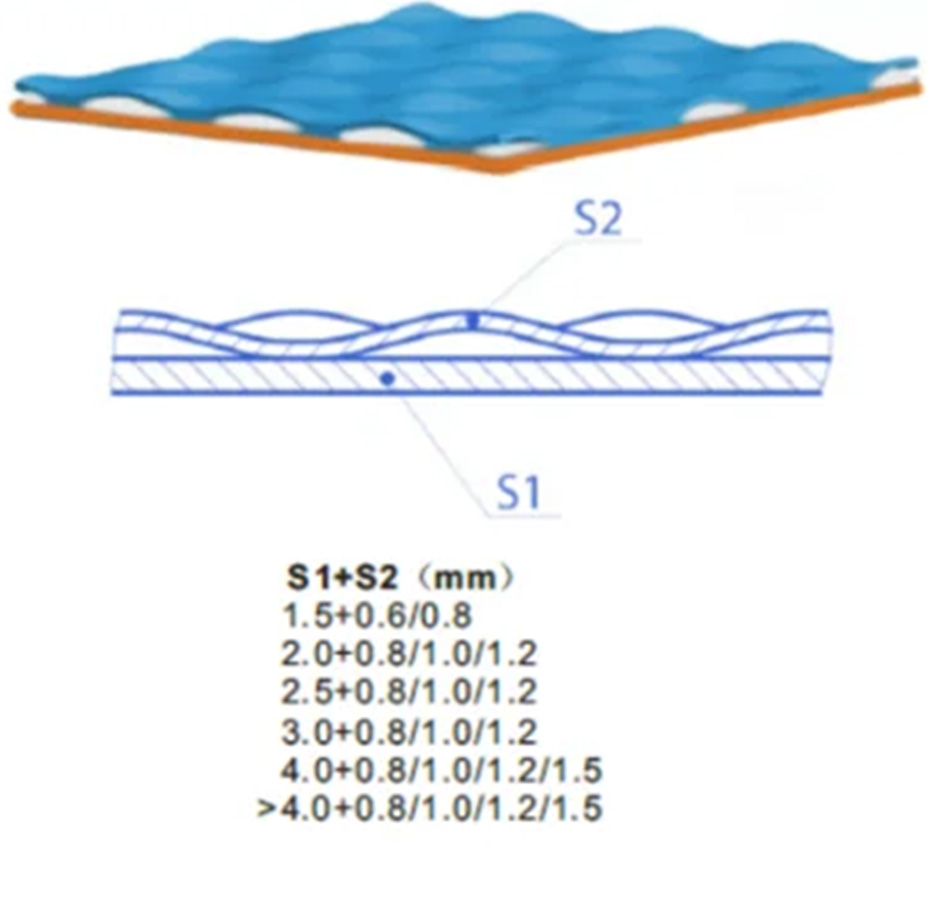

EMBLE EMBBOSED Plate

E bonts'a sebopeho se kenngoeng ka mahlakoreng ka bobeli.

1. Jacket jacket / Clamp-ON

3. Pina ea polasetiki plate "

5. Ice Bank bakeng sa polokelo ea leqhoa ea leqhoa

7. Cryting crystallizer

9. Setsebi sa metsi a thellang

11. Mocheso oa Sink oa mocheso

13. Moqomo oa ho polachoaive

2. Dimpled tanka

4. BAMPERSONS BATT CEMERES FEETING

6. Mochine oa leqhoa

8. Flue Khase Lat

10. Motsoako oa tokollo e kopanya mocheso

12. Bulk e tiileng ea mocheso o tiileng

1. Litemana tse nang le litsie tse phahameng li phalla pherekano e phahameng ho fihlela mokhoa o phahameng oa mocheso.

2. E fumaneha ka lisebelisoa tse ngata, joalo ka tšepe e se nang majoe a ss304, 316l, 2205 haslloyloy titanium le ba bang.

3. Boholo ba mofuta le sebopeho se fumaneha.

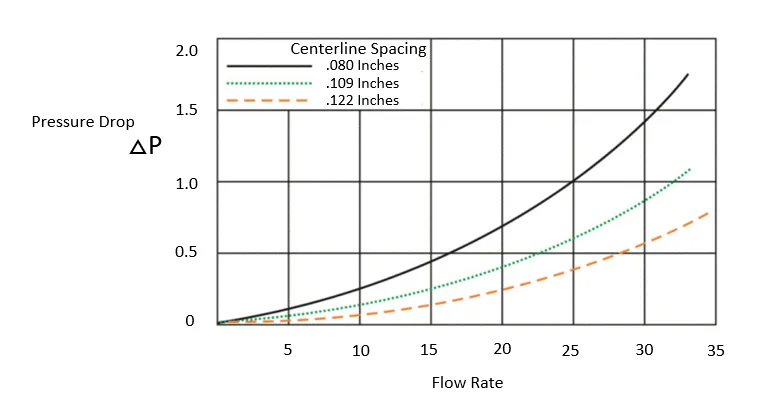

4. Tlas'a khatello e phahameng ea ka hare ke bareng ea 60.

5. Khatello e tlase ea khatello.