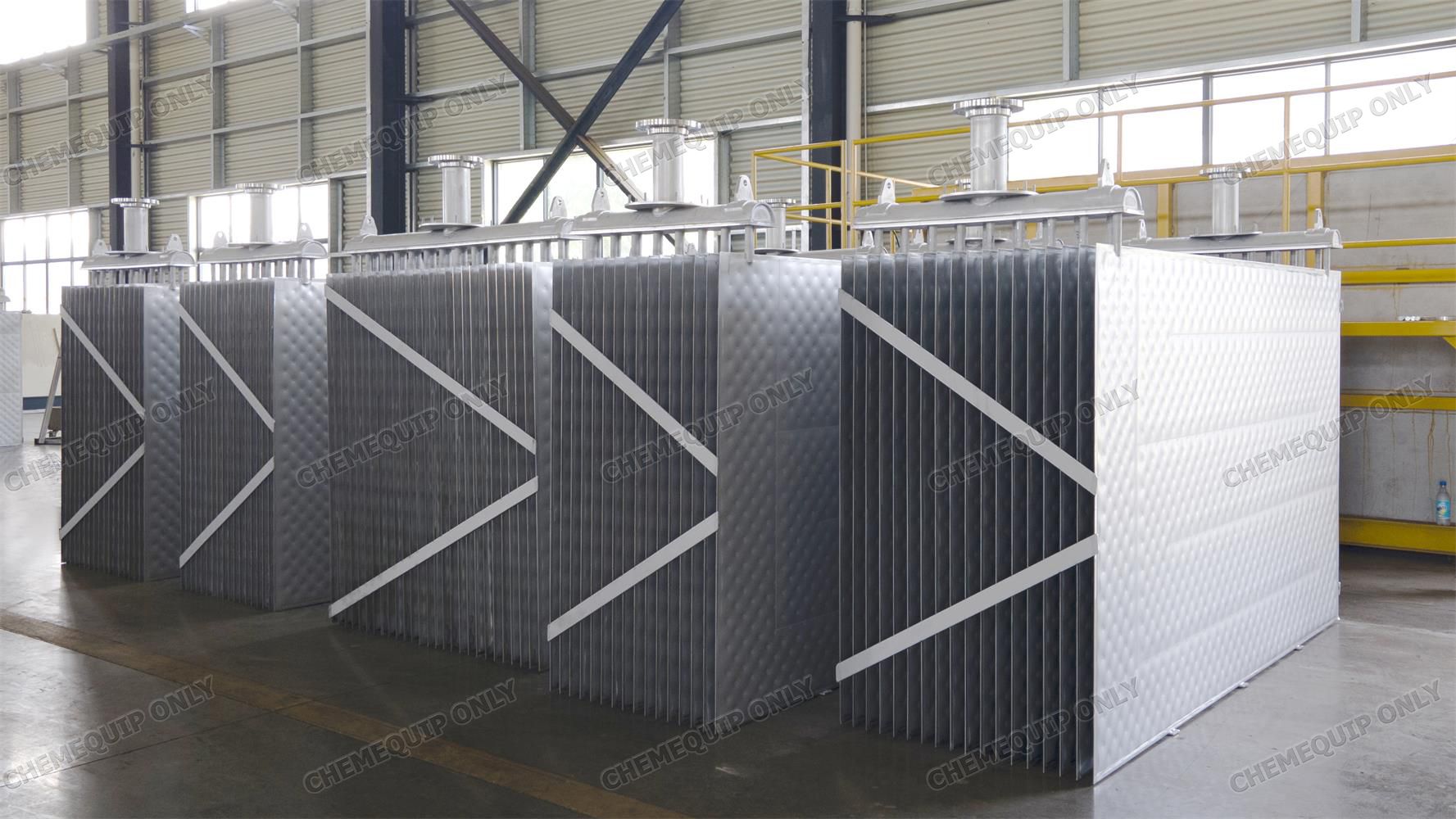

A tsaye narke masu kuka tare da maimaitawa pletoot faranti

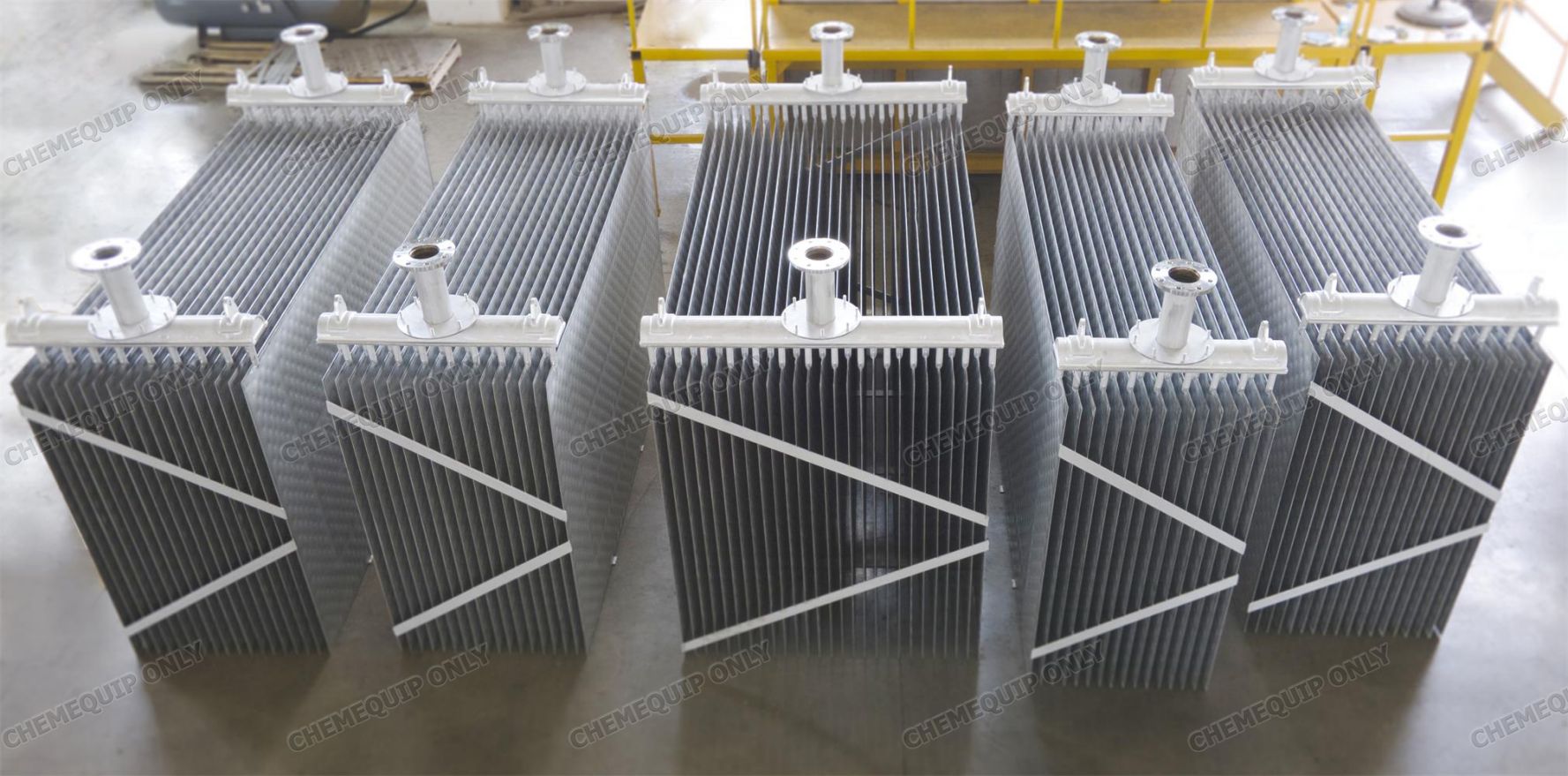

Static narke Cryststallizer yana amfani da farantin musayar zafi (farantin platecoil) tare da daskararren matsakaici ko matsakaici mai sanyi, wanda ake amfani da shi don tsarin yaduwar ciki ko tsarin sanyi. Ana sanya faranti a tsaye a cikin majalisar ministocin Cerstallizer, da dumama ko matsakaici mai sanyi a hankali yana hutawa ko sanyaya mace ruwa a ƙasa da daskarewa da molten abu. A ƙarshe, an kafa kifin lu'ulu'u a kan farantin canjin zafi, yana amfani da "heahing" don cire ƙazanta da tsarkake lu'ulu'u.

A tsaye narkewar krstallizer wata hanya ce ta tsarkake kuma rarrabe samfurin da ke tattare da matakai daban-daban wanda ya haɗa da ɗaukar matakan da ya haɗa da ɗaukar hoto guda uku wanda ya haɗa da ɗaukar matakan da ya haɗa da ɗaukar hoto guda uku wanda ya haɗa da ɗaukar matakan da ya haɗa da ɗaukar hoto guda uku waɗanda suka haɗa da ɗaukar matakan da suka haɗa da crystallization uku waɗanda suka haɗa da ɗaukar hoto, Sweating da narkewa.

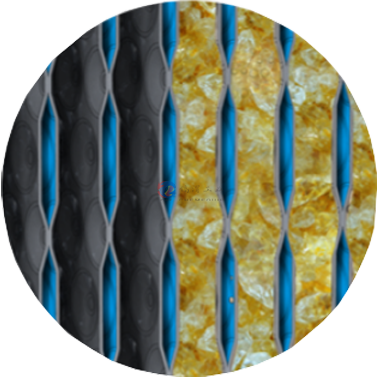

A hankali cakuda yana sanyaya sanyaya ta matsakaici canja wurin zafi da lu'ulu'u na ci gaba a farfajiya na faranti na farfadowa, samar da yadudduka masu yawa. Impurities galibi suna nan a cikin uwar giya kuma an kore ta daga kundin kira.

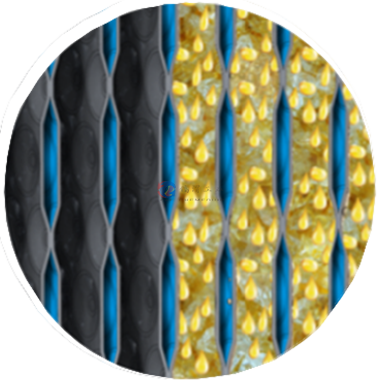

Za'a iya tsarkake murfin kuka ta hanyar zaki (wani bangare yana narkewa), watau jinkirin dumama zuwa ga narkewa, to, za a rinka zubar da su ta hanyar narke samfurin. Sweating shine babban mataki a cikin tsari gaba daya.

Bayan Switfating, zazzabi na matsakaici canja wurin zafi yana kara narke duk lokacin da kuka mai tsarkakakkun ruwa kuma sami babban samfurin ruwa.

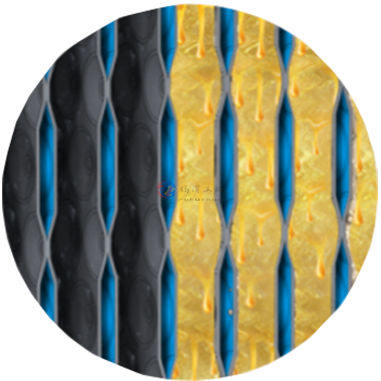

Platecoil farantin masariyar itace ne na musamman tare da farantin farantin wuta, wanda aka sanya ta Laser Welding da ruwa mai saurin shigowa da kuma yawan saurin canja wurin zafi. Za'a iya tsara LT kuma masana'anta a cikin fasali daban-daban da masu girma dabam bisa ga buƙatun abokin ciniki. An sanya farantin plateolil a cikin babban ƙarfi-ƙarfi. Wannan fasahar ta hada wani zane mai kauri-crystal-crystal-crystal-crarsting tare da wani matattarar fitarwa sarari da aka mutu a kasa. A waje na farantin platecoil-Free crystallier (static narke crstallizer) shine majalisar hukuma, tashar jiragen ruwa, tashar jiragen ruwa da sauran nozzles mai aiki.

| Karatun Commulronic | Magungunan petroum | ||

| Phosphoric acid | Ethylene carbonate | Parxylene | Benzene |

| Acetonitrile | Carbonate Vinylidene | 1,2,4,5-Tetramethylbenzene | Phenol |

| Dimethyl carbonate | Carbonate carbonate | Dicardcelopentariene | Parafin |

| Polymer monomers | Kyawawan sinadarai | ||

| Dl-lactide | Biyernol a | Sababbin abubuwa | Tdi |

| Dichlorobar | m-xylyleendiamine | Benzoic acid | Mdi |

| Succinonononitrile | Methacrylic acid | Chloro santic acid | Naphtarlene |

| 1,4-butafadiamamatine | Alanta na alakkar acid | 1-Naphthol | p-cresol |

| 1,4-dicyanobutane | Dimethyl ta cin amana | Metharylopphthalen | Benzoic acid |

| 1,6-Diaminohehexane | Teraphthamloy chloride | Cyneyroine | 4-chllotoluene |

| 1,5-Pentandesiamine | BIS (4-SPROOROPHANYL) - | Metholo | Maleic anhydride |

| BenzenceatIhine | BIS (4-Nithechnyl) eth | Dilisocyanate | Chloronitrobenzene |

| Copratoract | Dimeathyl Terephthatal | Dicardcelopentariene | P-Tert-butylphenol |

| Ilmin ilmin bi yakezali | |||

| Oleic acid | Maƙiyaci acid | Butane-1,2-Diol | Erythritol |

| I itaconic acid | Stearic acid | Crotonic acid | lsosorbide |

| Itacen cinnamic acid | Xylitol |

| |

1. Rarraba zazzabi.

2. Matsakaicin mai sarrafawa.

3. Ba a rushe lu'ulu'u lokacin gumi ba.

4. Cikakken cirewa don tsabtatawa da kiyayewa.

5. Girman kayan da aka yi da kuma sifar suna samuwa.