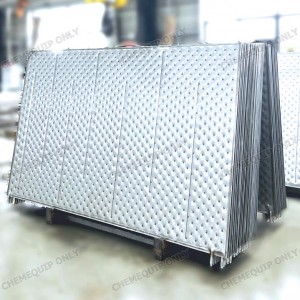

Milk Refrigeration Stainless Steel Cooling Dimple Jacket

The clamp-on heat exchanger is another variation of the pillow plate heat exchanger and can be directly attached to the outer surface of existing tanks or containers to facilitate cooling or heating. This type of heat exchanger can be manufactured in a double embossed construction, and with the use of heat conductive mud, it can also be produced in a single embossed or rolled shape to meet specific requirements. The clamp-on heat exchanger is also known by other names such as dimple jackets and stainless steel jackets.

The use of heat conductive mud enables the clamp-on heat exchanger to seamlessly conform to existing tanks or containers, effectively addressing issues related to flatness and heat exchange efficiency.

| Name | Specification | Brand | Material | Heat Transfer Medium | |

| Customizable Clamp on/Dimple Jacket | Length: custom-made Width: custom-made Thickness: custom-made |

Customers can add their own logo. | Available in most materials, including 304, 316L, 2205, hastelloy, titanium, and others | Cooling Medium 1. Freon 2. Ammonia 3. Glycol Solution |

Heating Medium 1. Steam 2. Water 3. Conductive Oil |

1. Can be mounted on the surface of existing tanks or container to provide the heating or cooling.

2. Dairy processing tank.

3. Beverage processing vessels.

4. Heating or cooling oil tank.

5. Various reactors.

6. Extruder-dryer.

7. Heat Sink.

8. Fermenters, beer vessels.

9. Pharmaceutical and processing vessels.

1. The inflated channels create the higher turbulence flow to achieve the higher heat transfer efficiency.

2. Available in most materials, like stainless steel SS304, 316L, 2205 Hastelloy titanium and others.

3. Custom-made size and shape are available.

4. Under the maximum internal pressure is 60 Bar.

5. Low pressure drops.

6. Low maintance and operating cost

7. Sturdy and Safety.