Manufacturer for Pillow Plate Jacket – Dimple Clamp-on Jacket – Chemequip Industries Co., Ltd.

Manufacturer for Pillow Plate Jacket – Dimple Clamp-on Jacket – Chemequip Industries Co., Ltd. Detail:

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Ice bank energy storage , Heating dimple tank , Plastic Plate Heat Exchanger , Welcome buddies from all over the earth come to visit, tutorial and negotiate.

Manufacturer for Pillow Plate Jacket – Dimple Clamp-on Jacket – Chemequip Industries Co., Ltd. Detail:

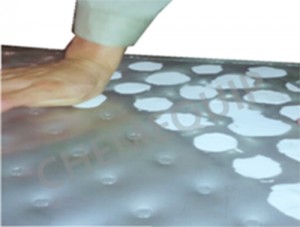

Heat Conductive Mud

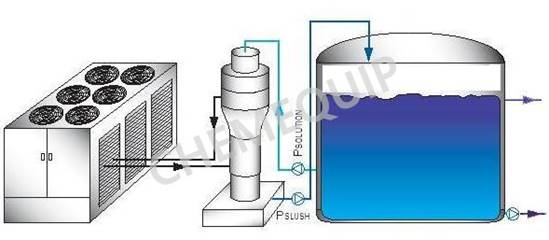

Dimple jacket is one of another form of pillow plates heat exchanger, and can be directly fit and stick to the outer surface of tanks or containers to realize the purpose for cooling or heating purpose.

The dimple jacket can be made into double embossed construction, by using heat conductive mud, the dimple jacket can fit perfectly to the tanks or containers, it also can be made a single embossed or rolled shape according to your requirements.

Dimple jacket /clamp-on will be firstly welded into a regular pillow plate/dimple plate, and then we can roll it or cut it according to your demands, finally we will inflate it into the shapes as your like.

When the dimple jacket/ clamp – on is finished completely, we will install and weld the connections and drains at the two corners of the clamp-on.

Dimple clamp-on jacket are usually mounted on the surface of existing tanks or container to provide the heating or cooling.

The dimple jacket can be used for oil tank outer wall heating/cooling??

The dimple jacket can be used as the conical head clamp-on

The dimple jacket can be widely used for dyeing heater

The dimple jacket can be used for equipment slotted clamp-on

The dimple jacket can be used in various reactors.

The dimple jacket can be used for the extruder-dryer

| 1. Hot Steam | 2. Hot Water |

| 3. Cooling Water | 4. Conduction Oil |

| 5. Freon Series R-22, R-502 | ? |

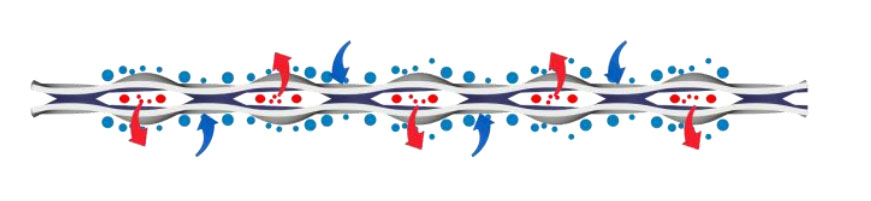

(1) Dimple embossed structure create the higher turbulence flow to achieve the higher heat transfer efficiency

(2) Stainless steel material 304 or SS316L with higher corrosion resistance for low maintenance cost

(3) Custom-made size and shape are available

(4) High pressure and extreme temperature are appliable

Our dimple jacket is widely applied to the the vessel outer surface cooling.