Hot sale Dimple Jacketed Tank – Laser Welded Tank – Chemequip Industries Co., Ltd.

Hot sale Dimple Jacketed Tank – Laser Welded Tank – Chemequip Industries Co., Ltd. Detail:

We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for Small Plate Heat Exchanger , Factory flue gas heat exchanger , Industrial off-gas(flue gas)cooler , Created solutions with brand price. We attend seriously to produce and behave with integrity, and because of the favor of clients in your own home and overseas in the xxx industry.

Hot sale Dimple Jacketed Tank – Laser Welded Tank – Chemequip Industries Co., Ltd. Detail:

The dimple plate tank is a stainless-steel cylindrical vessel that requires heating or cooling, it equips with a “jacket” made from dimple/pillow plates, as an integral part of the casing. Jacketed plates are welded by fiber laser welding machines, then it can be rolled in your desired shape. After installing the Jacket, the pillow plates are inflated.

There are three steps to form dimple plate tank:

1. Pillow/dimple plate is welded by fiber laser welding machine

2. The welded pillow/dimple plates are rolled by rolling machine

3. The rolled pillow plate are inflated

Note: flat welded plates are recommended to delivery for packing and shipping cost saved.

Step 1 Welding

?Step 2 Rolling

Step3?Inflation

Our dimple plate tank can be widely used for various cooling application:

(1) The dimple plate tank is widely used for dairy industry

(2) The dimple plate tank can be widely used for beer /wine /beverage processing industry

(3) The dimple plate tank is also applied to chocolate factories pre-cooling

(4) The dimple plate tank is suitable for fermenting factories

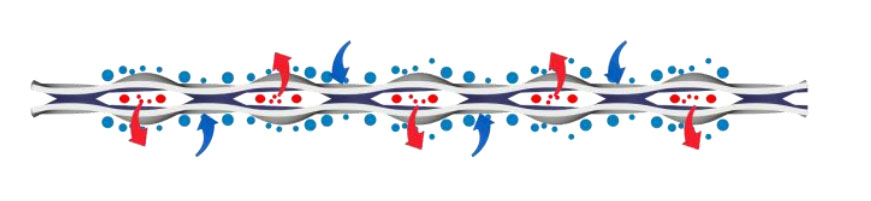

(1) Dimple embossed structure create the higher turbulence flow to achieve the higher heat transfer efficiency

(2) Stainless steel material 304 or SS316L with higher corrosion resistance for low maintenance cost

(3) Custom-made size and shape are available

(4) Low pressure drops

Our dimple jacket is widely applied to the the vessel outer surface cooling.