304 Stainless Steel Laser Welding Pillow Plate Falling Film Water Chiller Produces 0~1℃ Ice Water

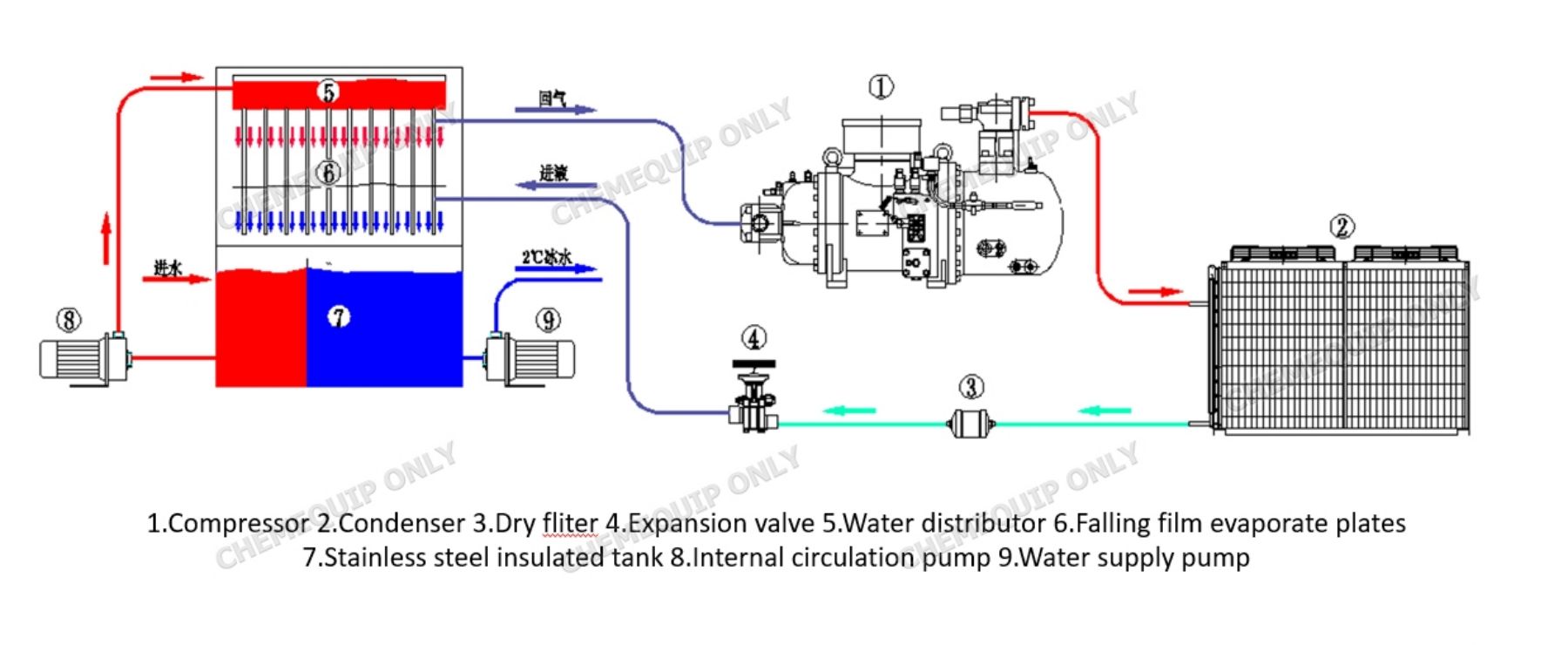

The falling film chiller primarily comprises pillow plate evaporators and a stainless-steel cabinet. It serves as a heat exchanger designed to cool water to the desired temperature, typically used for rapidly cooling large quantities of product. Within the falling film chiller, the pillow plate evaporators facilitate heat transfer from a thin film of liquid cascading on the exterior of the plates, while the refrigerant flows through the internal channels of the pillow plates. This setup enables efficient cooling of liquids across a broad temperature range.

The warm chilled water is pumped into the distribution tray and flows at a controlled rate from an overhead distribution panel, evenly cascading down the exterior of the Platecoil plates (also known as pillow plates) into the tank. Within the internal channels of the Platecoil plates, the cooling medium passes through, facilitating indirect heat exchange with the warm chilled water. As a result, the warm chilled water is cooled to the desired temperature by the cooling medium. Typically, the cooling medium includes Freon, Ammonia, Glycol, and special configurations that can operate with glycol in the presence of the refrigerant.

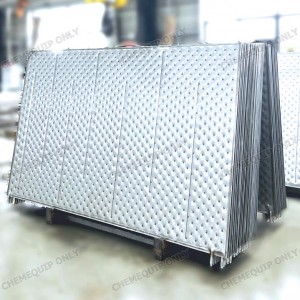

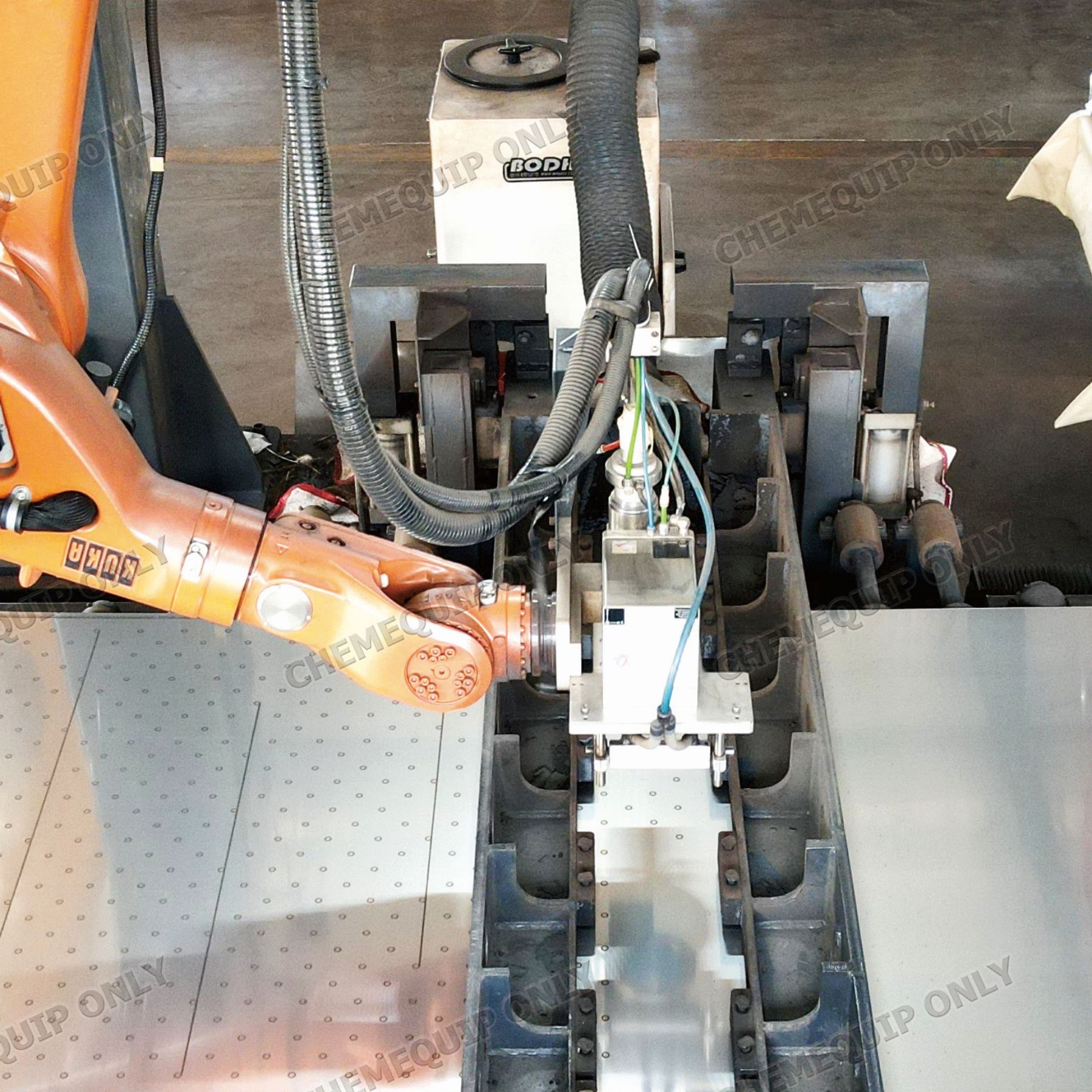

Platecoil plate is a special heat exchanger with a flat plate structure, formed by laser welding technology and inflated, with highly turbulent internal fluid flow, resulting in high heat transfer efficiency and uniform temperature distribution. lt can be designed and manufactured in different shapes and sizes according to customer's requirements. The exterior of the Platecoil plate is cabinet which designed with water distribution tray, outer door and so on. It can easily be cleaned, thanks to accessibility from all sides and space between the pillow plates evaporator.

|

Milk cooling production |

Blanching vegetables |

Poultry industry |

|

Cooling mussels/shrimp |

Cheese production |

Fish processing industry |

|

Bakery production |

Meat processing industry |

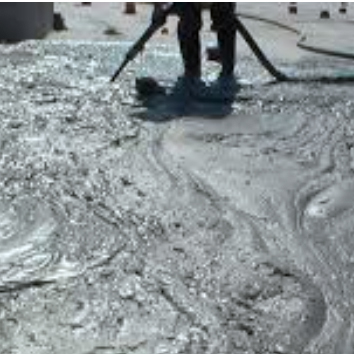

Construction industry (concrete) |

|

Chemical industries |

Pharmaceutical industries |

Coconut milk cooling |

1. Continuous and stable supply of 0-1°C water.

2. No mechanical distortion even when icing-up.

3. High heat transfer coefficient and low operating cost.

4. Platecoil plate structure for easy cleaning and maintenance.