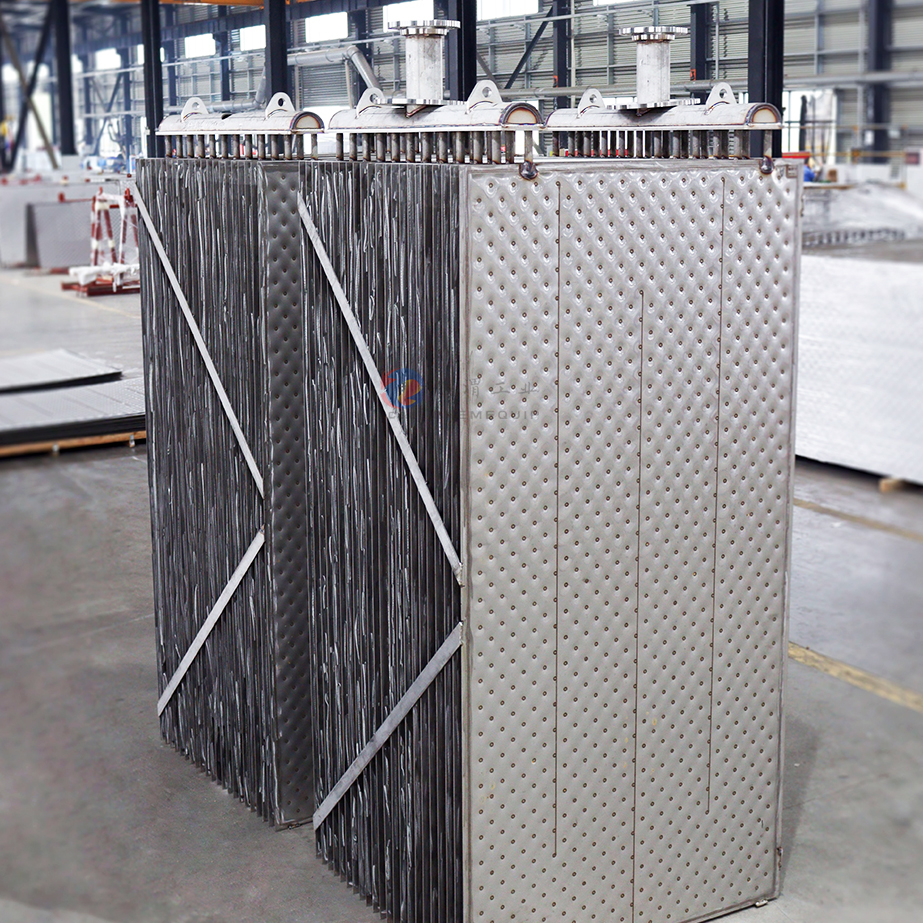

Laser Welded Pillow Plate Heat Exchanger

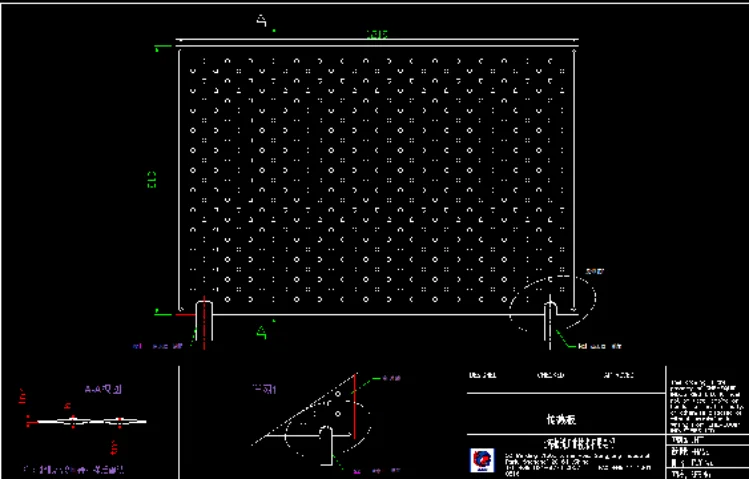

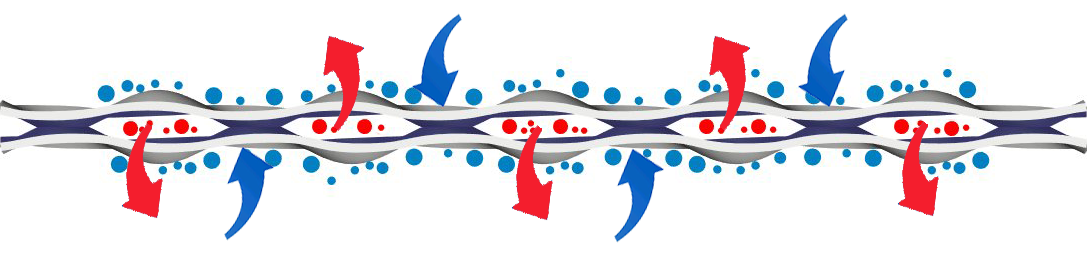

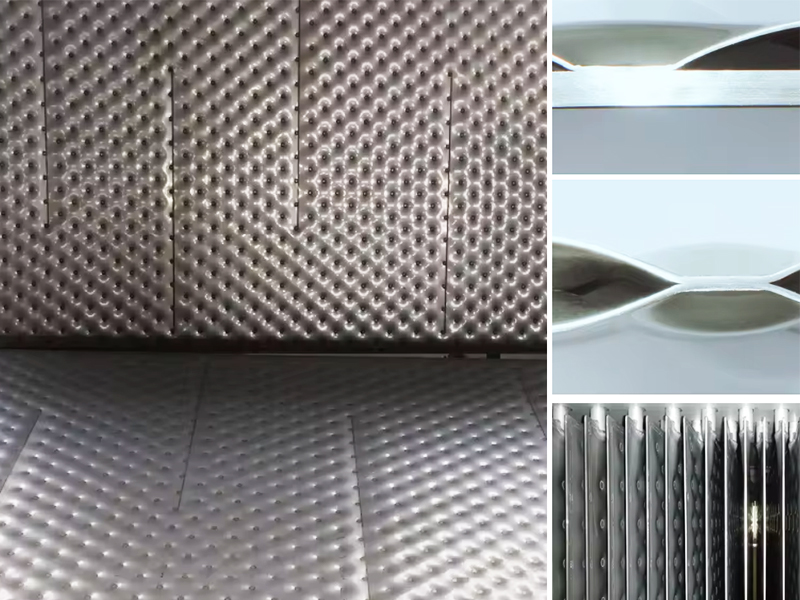

Pillow plate heat exchanger consists of two metal sheets, which are welded together by continuous laser welding. This panel-type heat exchanger can be made in an endless range of shapes and sizes. It is ideally suited for applications involving high pressures and temperature extremes, provides the highly efficient heat transfer performance. By the laser welding and inflated channels, it induces fluid great turbulence to attain high heat transfer coefficients.The pillow plate heat exchanger (also called pillow plate, dimple plate, thermo plate, cavity plate or evaporation plate, and so on.), consist of two stainless steel sheets laser welded together with a custom circle pattern.

| Name | Specification | Brand | Material | Heat Transfer Medium | |

| Customizable Pillow Plate Heat Exchanger | Length: custom-made Width: custom-made Thickness: custom-made |

Customers can add their own logo. | Available in most materials, including 304, 316L, 2205, hastelloy, titanium, and others | Cooling Medium 1. Freon 2. Ammonia 3. Glycol Solution |

Heating Medium 1. Steam 2. Water 3. Conductive Oil |

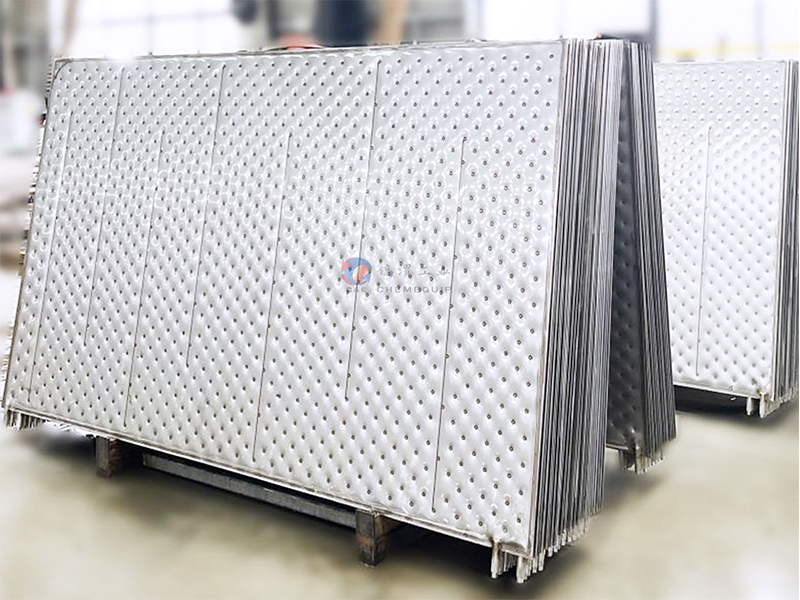

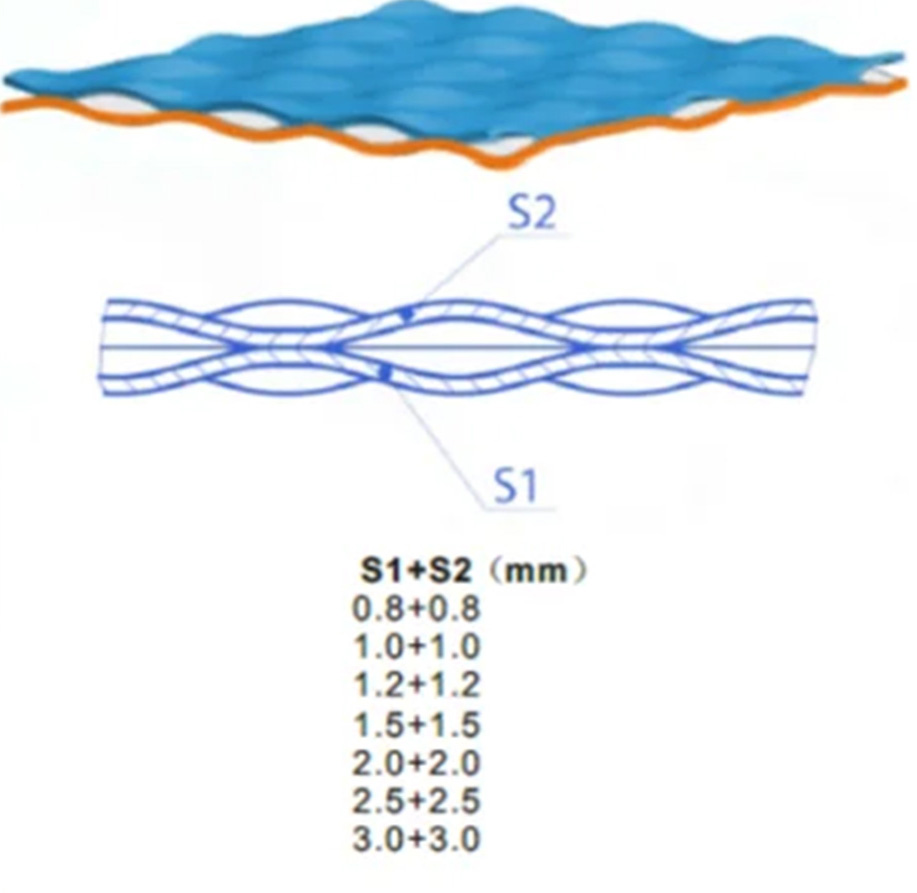

Double Embossed Pillow Plate

It shows a inflated structure on both sides.

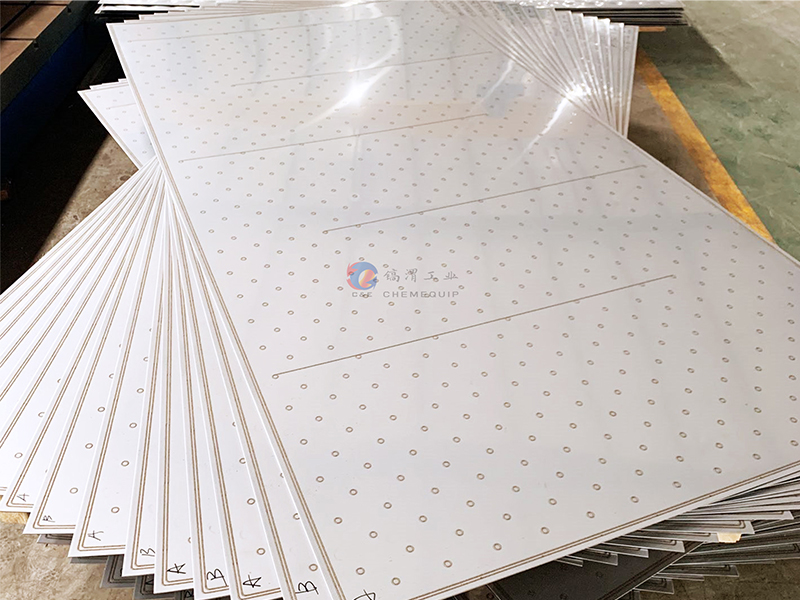

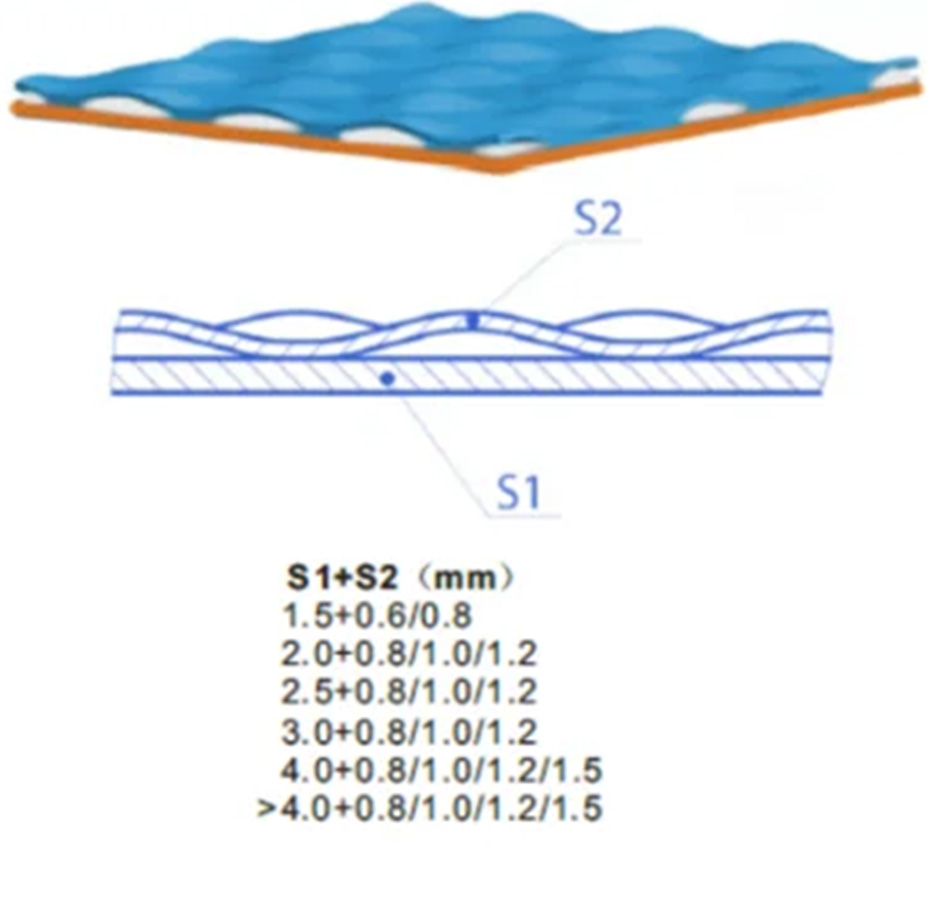

Single Embossed Pillow Plate

It has one inflated side and one flat side.

1. Dimple Jacket /Clamp-on

3. Pillow Plate Type Falling Film Chiller

5. Ice Bank for for Ice Thermal Storage

7. Static Melting Crystallizer

9. Sewage Water Heat Exchanger

11. Heat Sink Heat Exchanger

13. Evaporative Plate Condenser

2. Dimpled Tank

4. Immersion Heat Exchanger

6. Plate Ice Machine

8. Flue Gas Heat Exchanger

10. Reactor Intermal Baffles Heat

12. Bulk Solid Heat Exchanger

Static Melting Crystallizer

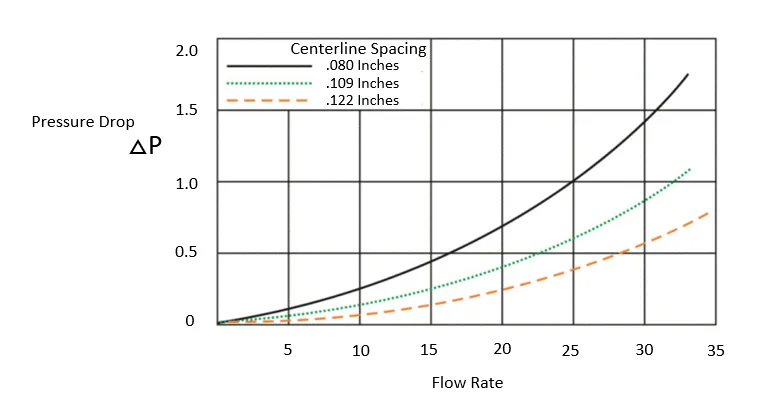

1. The inflated channels create the higher turbulence flow to achieve the higher heat transfer efficiency.

2. Available in most materials, like stainless steel SS304, 316L, 2205 Hastelloy titanium and others.

3. Custom-made size and shape are available.

4. Under the maximum internal pressure is 60 Bar.

5. Low pressure drops.